Automation

Clearance

EZ-Automation Solutions

Manufacturers face significant challenges daily. First, there's fierce competition for skilled workers amid rising labor and benefit costs, and delivering quality parts on time adds to the pressure. Automation can be a solution, offering efficiency and cost-effectiveness, especially with tight deadlines and workforce shortages.

Moreover, customers increasingly demand high mix, low volume quality parts. Yet, the variability in machining various products poses hurdles for automation implementation. Additionally, modernizing for Industry 4.0/5.0 is complex. Integrating, operating, and maintaining such systems cost-effectively with existing staff skill sets is daunting.

However, automation is no longer futuristic; it's essential for success today. Simplifying the journey towards machine tending and lights-out machining is crucial. This requires user-friendly automation solutions, minimizing the need for advanced robotics or automation skills. It's about seamlessly integrating automation while controlling costs and easing job complexities for manufacturers.

Today, you can enable your machine shop at any size to thrive with streamlined operations, improved processes, and a bottom line that reflects your success.

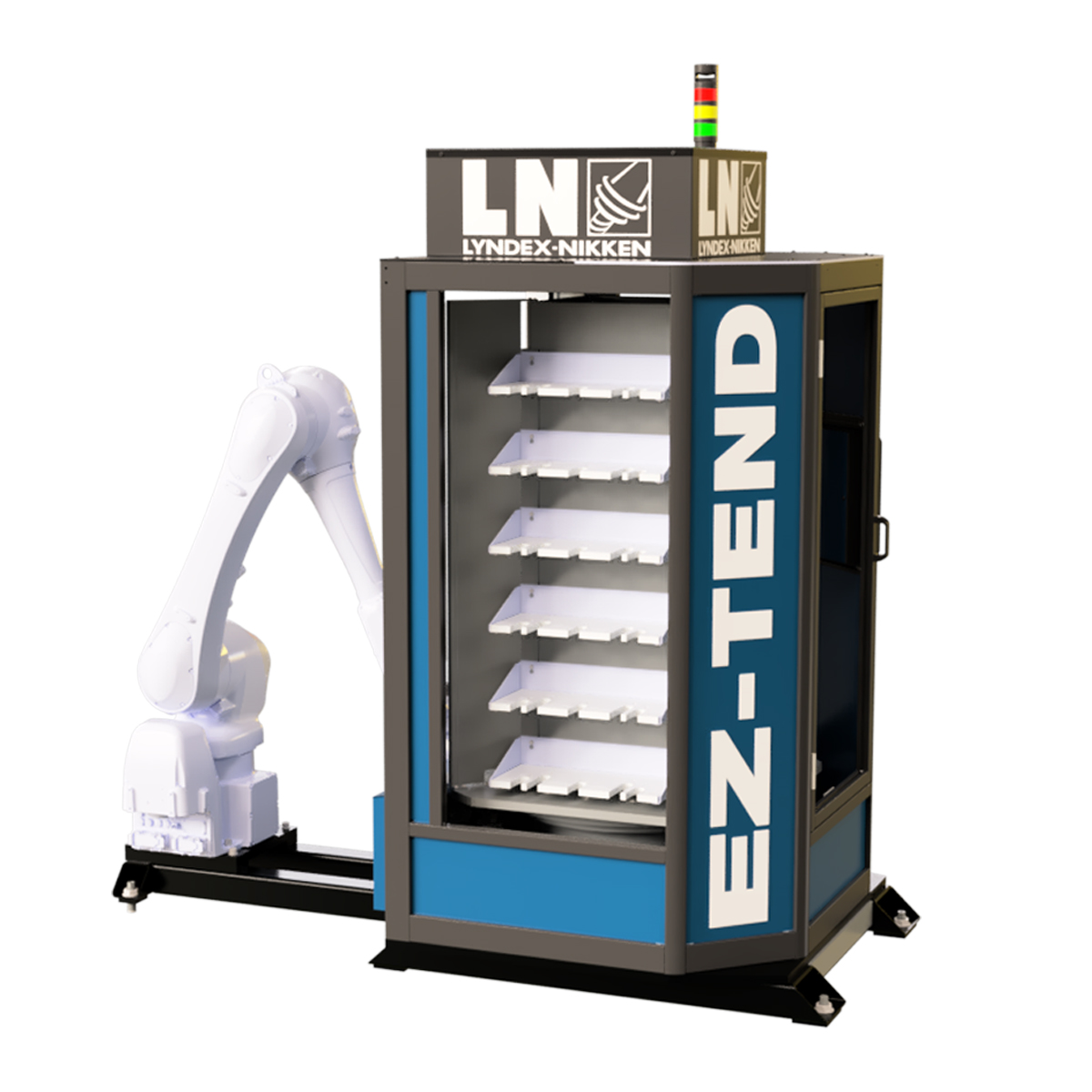

Lyndex-Nikken is your partner in growth and we’re here to make easy automation work for you with the EZ-Automation line of solutions - NO advanced robotics degree required. The EZ-Automation line of solutions includes:

- EZ-AutoCart: Easily Automate CNC Machine Tending

- EZ-Cob: CNC Machine Loading Automation Solution

- EZ-Bot: Automatic Work Changer for 5-Axis CNC Machine

- EZ-Tend: Modular CNC Machine Tending Platform

- EZ-SmartTower: Increase Machine Shop Efficiency with Machine Tracking System

EZ-AutoCart – Easily Automate CNC Machine Tending

The EZ-AutoCart machine tending solution empowers machine shops to automate the tending of CNC lathes, mills, and similar machines, significantly boosting spindle time and enhancing overall machine efficiency.

Additionally, designed into the software is the ability to expand functionality as you grow with your robot. You can harness the power of expressions to provide a flexible and robust solution for custom automation needs.

EZ-AutoCart integration capabilities:

- Includes 16 digital I/O to control peripheral devices

- Manage auto doors open/close

- Manage workholding conditions

- Optional hub provides data mining and quick change between multiple CNC machines

- Monitor CNC machine conditions

EZ-AutoCart vision capabilities:

- Includes integrated camera for 2/3D vision

- Optional software for 2.5D picking

EZ-AutoCart is designed for machine tending:

- Payload capacity: 18kg

- Reach: 1300mm

- Max joint speed: 435°/s

- Repeatability: +/-0.025mm

EZ-AutoCart system includes:

- Robot arm, cart, and tablet

- Support, including joint and hardware replacements

- Options (not included): Workholding, end-of-arm tooling, fixturing plates for the cart, safety scanners, and integration support.

EZ-Cob – CNC Machine Loading Automation Solution

Coming soon!

EZ-Bot – Automatic Work Changer for 5-Axis CNC Machine

Coming soon!

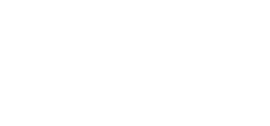

EZ-Tend – Modular CNC Machine Tending Platform

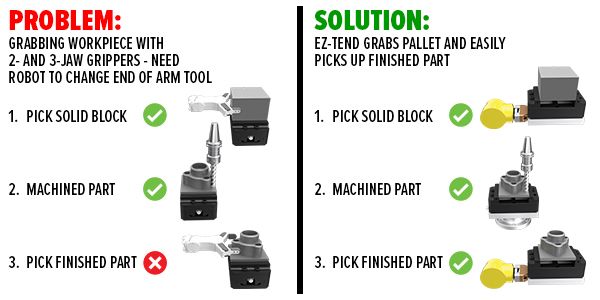

As a manufacturer, when trying to grab workpieces with 2- and 3-jaw grippers you can run into several challenges:

- Grab square/rectangle block

- Perform a machining operation

- No parallel surfaces to grab

Your automation journey starts to get complex; you now need a robot that can change its end of arm tool (EOAT) to accommodate the irregular shape. This is expensive and, in many cases, not possible.

What is needed is an automation solution that doesn’t deal with the changes in part geometry or the workholding issues. Utilizing a proven lean manufacturing technique, grabbing a single point on a pallet and moving the pallet and its contents to its destination will allow you to:

- Machine any shape

- Create part density

- Freely access sides of part as needed

Ideal for high mix/low volume production, the EZ-Tend modular CNC machine tending platform is an approachable, easy-to-use industrial robotic machine tending system. The EZ-Tend is an off-the-shelf automation experience. Great for the first time industrial robotic user entry level or the professional wanting ease of use and setup of industrial robot tending.

EZ-Tend leverages lean principles by taking the application of lean manufacturing to the next level by using robots to tend the CNC machine to do lean tending. Its flexibility and power allow it to service milling centers with an option for turning centers.

The power of the EZ-Tend lies in the preconfigured pick and place positions. No robot programming required.

Manufacturers using the EZ-Tend will benefit with:

- One operator can run multiple machines

- Less operators mitigates cost increases

- Spindles run significantly more with assistance from automation

- High efficiencies equal improved capacity utilizations

- More throughput with the improved efficiencies

- Competition issues are mitigated due to better efficiencies, more throughput, and less cost

The EZ-Tend system uses mechanical design elements to provide protection from interaction with mechanical movement to offer the optimum level of operator safety. Optional state-of-the-art laser scanners are available.

The EZ-Tend system’s HMI (Human Machine Interface) is designed for the novice. The intent is to allow a non-robot programmer to create a pick and place routine using an icon base menu with just 3 screens to set up a new program. This simplicity is designed into the EZ-Tend system.

EZ-SmartTower – Increase Machine Shop Efficiency with Machine Tracking System

Coming soon!

If you want to dramatically improve your manufacturing potential, you need to automate. You can enable your machine shop at any size to thrive with streamlined operations, improved processes, and a bottom line that reflects your success.

Lyndex-Nikken is already well-known on the shop floor for machine tool accessories and is now meeting the demands of industry with automation solutions. Contact us today, and we’ll show you what your return on investment could be.

Videos: Why Manufacturers Choose Lyndex-Nikken Solutions for Machine Tool Accessories and Automation

Hear and see for yourself how Lyndex-Nikken quality machine tool accessories and automation provide optimal machining solutions for: